Here is a complete, professional English translation, suitable for technical brochures, academic materials, or high-end B2B marketing content:

Laboratory Mixing Granulator Demonstrates Outstanding Advantages in Experimental Precision and Equipment Durability, Primarily Reflected in the Following Dimensions:

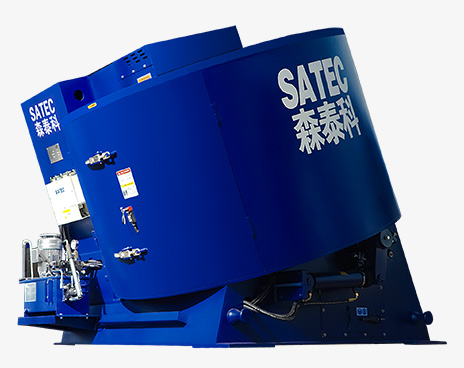

Mixing Granulator

Intelligent Control System

Adopting a dual-mode PLC + HMI control architecture, the system enables digital setting and dynamic compensation of key parameters such as rotational speed, temperature, and mixing time. Process curves are optimized through PID algorithms, ensuring batch-to-batch deviation of less than 0.5%.

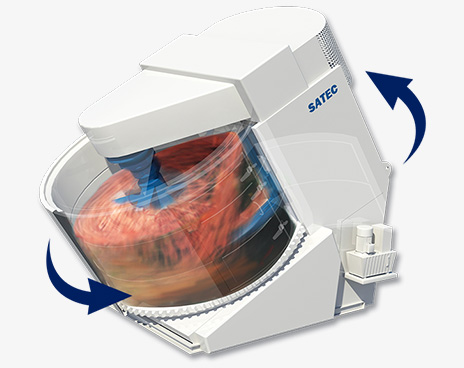

Multi-Physical Field Coupled Design

The unique screw configuration and barrel structure generate a controllable shear force field. Combined with vacuum/pressure-assisted systems, micro-level mixing efficiency is increased by 40%. Nano-scale tracer experiments verify a uniformity level of up to 99.2%.

Online Monitoring Technology

Integrated infrared temperature sensors and torque monitoring modules provide real-time feedback on material status. When viscosity fluctuations exceed preset thresholds, the system automatically compensates by adjusting rotational speed, ensuring high experimental reproducibility.

Military-Grade Structural Design

Critical components are manufactured with nitrided titanium alloy, while the main shaft undergoes finite element topology optimization, resulting in a threefold improvement in fatigue strength. A dual-bearing sealing system enables over 5,000 hours of continuous fault-free operation.

Modular Functional Units

Core components adopt a quick-release design, allowing maintenance to be completed within 30 minutes. The barrel lining features food-grade ceramic coating, offering wear resistance up to eight times higher than that of conventional equipment.

Environmental Adaptability

With an IP65 protection rating and an independent temperature-control enclosure, the system operates stably across a wide temperature range from –40°C to 200°C. A specially designed self-cleaning program effectively prevents residual cross-linked materials.

Through the integration of precision mechanical engineering and intelligent control systems, this equipment not only meets laboratory requirements for high-precision formulation development with micro-batch sizes as low as 50 g, but also demonstrates a service life exceeding 10,000 cycles under continuous high-load testing—providing reliable support for new material development. Its unique flow-field simulation capability and AI-based parameter optimization algorithms are driving laboratory granulation technology toward a new era of intelligent manufacturing.

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory