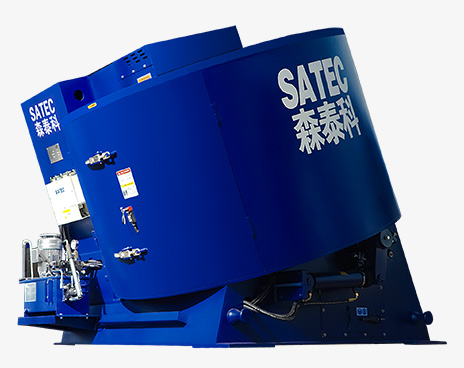

Intensive Mixers for Lithium Battery Material Processing

High-Precision Intensive Mixing Solutions by SATEC

Introduction to Intensive Mixers in Lithium Battery Production

Introduction to Intensive Mixers in Lithium Battery Production

Lithium battery material processing requires extremely high standards of mixing uniformity, consistency and process stability. Whether producing cathode materials, anode materials or conductive additives, precise mixing plays a critical role in battery performance and lifecycle.

Industrial intensive mixers are widely adopted in lithium battery production due to their high shear mixing capability and controlled material circulation.

SATEC intensive mixers provide reliable and scalable solutions for lithium battery manufacturers seeking stable quality and efficient production.

Mixing Challenges in Lithium Battery Material Processing

Lithium battery materials present unique mixing challenges:

Fine powders with high surface area

Sensitive material ratios affecting electrochemical performance

Risk of agglomeration and poor dispersion

Strict requirements for batch-to-batch consistency

Conventional mixers often struggle to meet these demands, especially in high-performance battery material production.

Why Intensive Mixers Are Ideal for Lithium Battery Applications

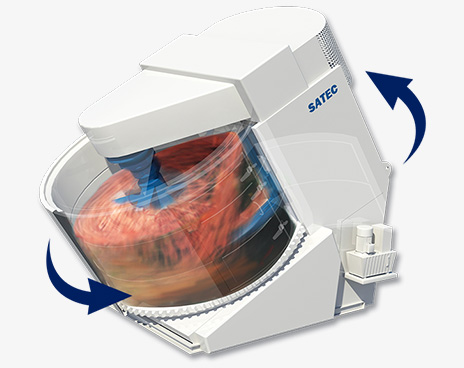

High Shear Mixing for Uniform Dispersion

Intensive mixers generate controlled high shear forces that effectively disperse active materials, binders and conductive additives, ensuring uniform composition.

Precise Process Control

Advanced control systems allow accurate adjustment of mixing parameters, helping maintain consistent quality across batches.

Stable and Repeatable Results

Forced material circulation eliminates dead zones and improves mixing reliability, which is critical for lithium battery material performance.

Adaptability to Different Battery Materials

Intensive mixers can be configured for both cathode and anode material processing, supporting various formulations and production scales.

Typical Lithium Battery Applications of Intensive Mixers

SATEC intensive mixers are used in multiple lithium battery material processes, including:

Cathode material preparation

Anode material mixing

Conductive additive dispersion

Pre-granulation and material homogenization

Advanced battery material research and production

This versatility makes intensive mixing technology suitable for both pilot-scale and industrial production lines.

Key Design Features of SATEC Intensive Mixers for Battery Materials

Sealed and Dust-Controlled Design

The enclosed mixing structure helps minimize dust emission and protects sensitive battery materials during processing.

Precision Mixing Tools

Optimized mixing tools ensure efficient shear force distribution without damaging material structure.

Clean and Easy Maintenance

Smooth internal surfaces support easy cleaning and reduce the risk of cross-contamination between batches.

Intelligent Automation System

PLC-based control systems provide stable and repeatable operation for high-value battery materials.

Benefits of Using SATEC Intensive Mixers in Battery Material Production

Improved material uniformity

Enhanced electrochemical consistency

Reduced material loss and waste

Stable batch quality for large-scale production

High reliability and long service life

These benefits help lithium battery manufacturers improve product performance and production efficiency.

Customized Intensive Mixer Solutions for Lithium Battery Plants

As a professional intensive mixer manufacturer, SATEC offers customized solutions tailored to lithium battery production requirements, including:

Batch size and capacity optimization

Material-specific mixing configurations

Integration with upstream and downstream processes

Support for pilot and mass production lines

Our engineering team works closely with customers to deliver optimized intensive mixing systems.

Why Choose SATEC for Lithium Battery Intensive Mixing Equipment

Why Choose SATEC for Lithium Battery Intensive Mixing Equipment

SATEC combines advanced intensive mixing technology with robust industrial design to support the demanding requirements of lithium battery material processing.

With factory-direct manufacturing, strict quality control and professional technical support, SATEC provides reliable intensive mixer solutions for battery manufacturers worldwide.

Contact SATEC for Lithium Battery Intensive Mixer Solutions

If you are looking for industrial intensive mixers for lithium battery materials, contact SATEC for technical consultation and customized mixing solutions.

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory