Industrial Intensive Mixers for High-Efficiency Material Processing

Industrial Intensive Mixers for High-Efficiency Material Processing

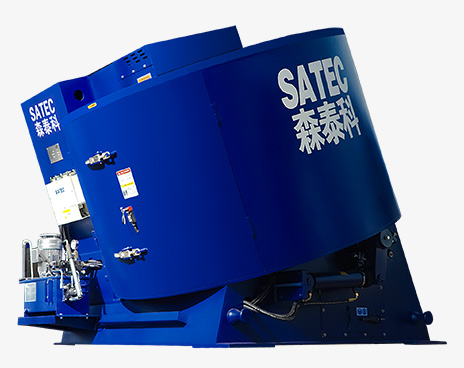

SATEC Intensive Mixing Equipment

Overview of SATEC Industrial Intensive Mixers

The industrial intensive mixer shown above is a core product developed and manufactured by SATEC, designed for high-efficiency mixing, granulation and homogenization of complex materials.

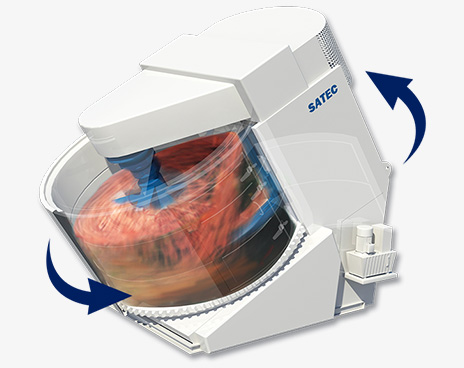

This intensive mixer integrates high shear mixing, forced circulation and precise process control into a compact and robust structure, making it ideal for industries that require uniform mixing, controlled particle size and stable batch quality.

Compared with conventional mixers, SATEC intensive mixers achieve faster mixing cycles, higher material uniformity and excellent adaptability to a wide range of powders, granules and moist materials.

Key Structural Features of the SATEC Intensive Mixer

High-Strength Mixing Pan

The cylindrical mixing pan is manufactured from high-strength steel and engineered to withstand continuous industrial operation. Its optimized geometry promotes effective material circulation and minimizes dead zones during mixing.

Intensive Mixing Tool System

The centrally mounted mixing tools generate high shear forces, ensuring rapid dispersion and uniform distribution of materials. The blade configuration can be customized based on material characteristics such as particle size, moisture content and bulk density.

Integrated Feeding & Discharge Design

The top feeding inlets allow precise material input, while the large front discharge door enables fast and complete emptying. This design significantly reduces batch changeover time and improves production efficiency.

Hydraulic Door & Sealing System

The hydraulic discharge door ensures reliable sealing during mixing and smooth operation during discharge, preventing material leakage and maintaining a clean working environment.

Industrial Control System

The intensive mixer is equipped with a PLC-based control system, enabling accurate control of mixing time, speed and process parameters. Automation ensures consistent results across batches and simplifies operation.

Advantages of SATEC Intensive Mixers

High shear mixing for fast and uniform material processing

Excellent adaptability to dry, moist and granulating materials

Robust industrial design for long service life

Customizable mixing tools and capacity options

Easy cleaning and maintenance

Stable performance for continuous production

These advantages make SATEC intensive mixers a competitive alternative to well-known brands such as EIRICH, AKW and CO-NELE.

Typical Applications of Intensive Mixing Equipment

SATEC industrial intensive mixers are widely used in:

Lithium battery materials (cathode & anode powders)

Refractory materials

Ceramics and advanced materials

Chemical powders and compounds

Building materials and special mortars

Metal powders and composite materials

The intensive mixing technology ensures consistent material properties, which is critical for downstream forming, granulation and sintering processes.

Custom Intensive Mixer Solutions

As a professional intensive mixer manufacturer, SATEC provides customized solutions based on customer requirements, including:

Mixing capacity and batch size

Material type and process flow

Wear-resistant or corrosion-resistant linings

Customized mixing tool configurations

Integration with upstream and downstream equipment

Our engineering team works closely with customers to deliver optimized intensive mixing systems for specific production needs.

Why Choose SATEC as Your Intensive Mixer Manufacturer

SATEC focuses on delivering reliable, high-performance industrial intensive mixers with strong technical support and flexible customization.

With in-house manufacturing, strict quality control and extensive application experience, SATEC helps customers improve mixing efficiency, product consistency and overall production performance.

Contact SATEC for Intensive Mixer Solutions

If you are looking for industrial intensive mixers or customized intensive mixing equipment, contact SATEC today for technical consultation and quotation.

Environmental friendly

Environmental friendly Lithium battery

Lithium battery Chemical Industry

Chemical Industry Catalyst

Catalyst Ceramic

Ceramic Medical Food

Medical Food Metallurgy

Metallurgy Carbon

Carbon Fertilizer

Fertilizer Building materials

Building materials Foundry Sand

Foundry Sand Welding Flux

Welding Flux Glass

Glass Refractory

Refractory